VULNERABILITY

MANAGEMENT

Know your weak spots

- and fix them fast.

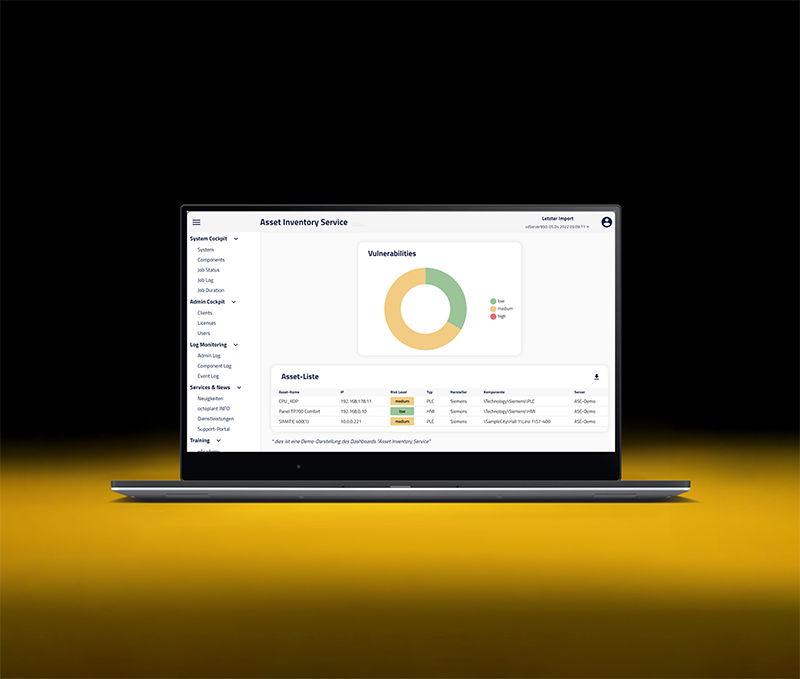

Octoplant gives manufacturers visibility into security weaknesses across their automation assets by identifying software versions, missing patches, and known vulnerabilities. By continuously mapping asset data to global vulnerability databases (such as CVE), Octoplant allows OT teams to proactively address issues before they can be exploited. In environments where outdated firmware or undocumented system changes are common, having accurate, device-level insights into risk exposure is essential for maintaining uptime, regulatory compliance, and production safety. Octoplant integrates with existing engineering workflows to ensure vulnerabilities are flagged, prioritized, and resolved without disrupting operations.

Continuous

access

access

to CVE databases to match vulnerabilities with known device and software data

Device-specific

risk scoring

risk scoring

to highlight the impact and urgency of each vulnerability

Detailed

reports

reports

on outdated firmware, unsupported software versions, or misconfigurations

Prioritized

remediation

remediation

recommendations based on severity, asset criticality, and exposure

Clear

guidance

guidance

for patches, upgrades, or configuration changes

Continuous

reassessment

reassessment

of the security posture as environments evolve

Visibility across multiple sites

deployments to align local actions with global policies

Support for compliance reporting

aligned with industry standards and internal governance

Close the Gaps Before They’re Exploited

Unpatched vulnerabilities in OT systems are among the leading causes of cyber incidents in industrial environments. Octoplant helps you stay ahead by making hidden risks visible and actionable. Its vulnerability management solution continuously matches device and firmware data with public CVE databases, identifying security gaps across your production environment - without requiring active scans or manual audits.

Each vulnerability is assessed using criticality scores based on the CVSS framework, helping teams focus on high-impact threats first. Asset-specific details, including vendor, model, and firmware version, provide clear context for remediation and decision-making. With centralized visibility across all sites, octoplant scales effortlessly for complex industrial setups, turning vulnerability management into a proactive, embedded function. This transforms what was once a reactive checklist into a continuous safeguard for the integrity of your automation systems, supporting compliance and long-term operational resilience.