WE'VE

GOT YOU

COVERED

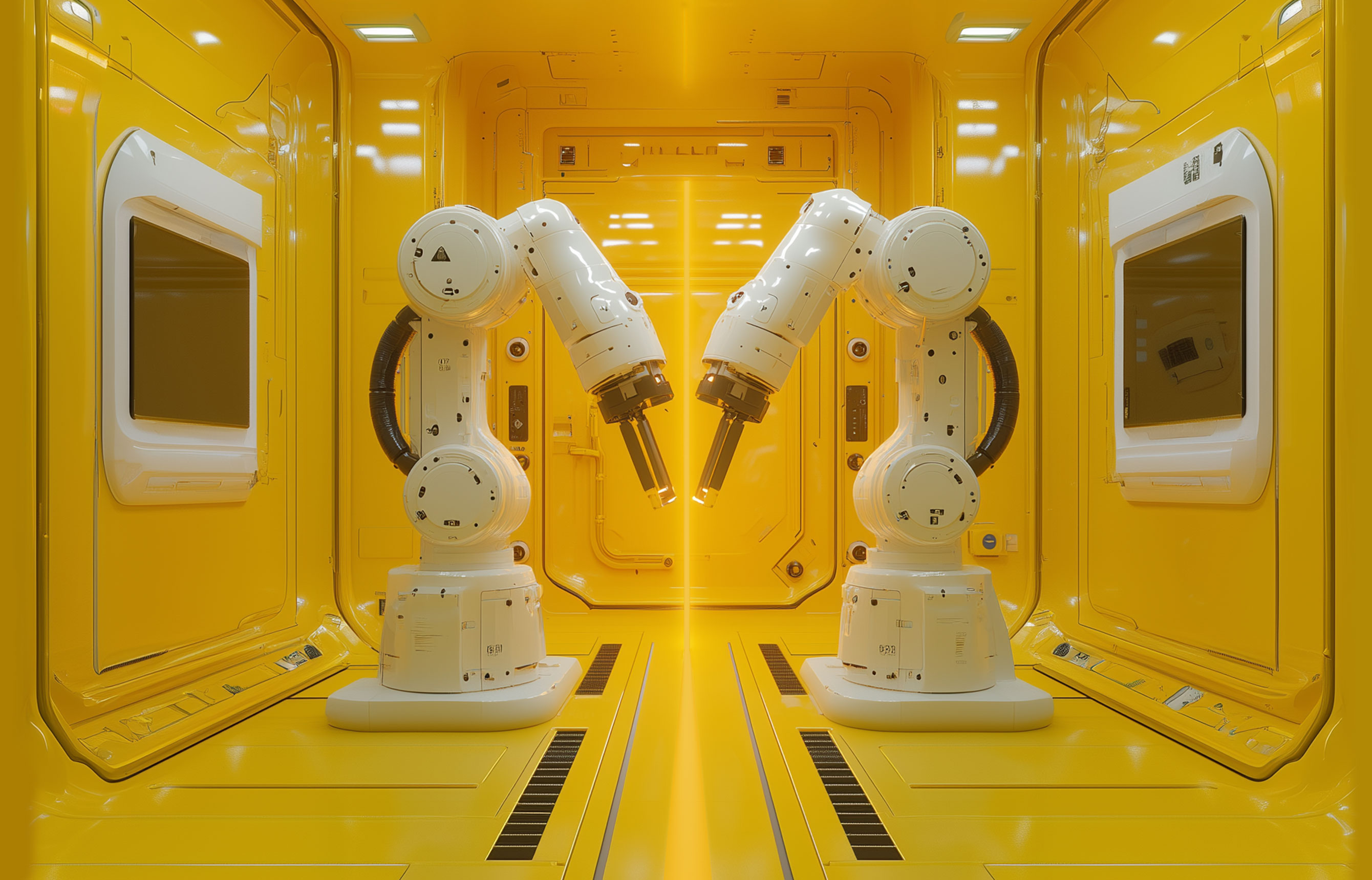

THE ULTIMATE

PRODUCTION RESILIENCE

AND OT SECURITY

SOFTWARE

NOT ON

YOUR WATCH

YOUR WATCH

Nobody wants a disaster at the plant, especially one that becomes infamous. To avoid costly and stressful setbacks, we’ve spent over 40 years developing octoplant - the ultimate production security software - ensuring that such incidents won’t happen on your watch, or anyone else's.

KEEPING PRODUCTION

IN PERFECT BALANCE

IN PERFECT BALANCE

AUTOMOTIVE

Safeguard complex production lines by ensuring fast recovery, secure versioning, and full visibility across automation assets to maintain high output and uptime.

FOOD AND BEVERAGES

Protect food production environments with reliable version control and compliance tracking, reducing risks of unplanned downtime and ensuring traceable, hygienic operations.

UTILITIES

Enhance operational stability and cybersecurity by managing vulnerabilities, supporting regulatory compliance, and minimizing recovery time from disruptions.

PHARMA AND HIGHLY REGULATED

MANUFACTURING

MANUFACTURING

Ensure compliance and audit readiness through secure asset management, change tracking, and consistent versioning tailored for validated, high-standard environments.

LOGISTICS

Boost logistics performance by reducing system interruptions, enabling instant recovery, and securing configurations across distributed sites and moving assets.

OEM (MACHINE BUILDING)

Empower machine builders to deliver secure, maintainable systems with version control, instant restore options, and proactive monitoring across installed bases.

INDUSTRIAL

SYSTEMS

BACKUP

SYSTEMS

BACKUP

Get vendor-angostic, secure, automated backups that regularly capture production data, ensuring a reliable system image. It saves time, reduces errors, and keeps the right version available for quick recovery.

VERSIONING,

VERSION CONTROL

AND MANAGEMENT

VERSION CONTROL

AND MANAGEMENT

Gain full visibility into all changes in your production environment. Powerful version management lets you track, revert, and manage versions of documents, code, and systems - ensuring transparency, traceability, and seamless collaboration.

CHANGE

MANAGEMENT

MANAGEMENT

Achieve precise control over changes made by service providers, ensuring transparency and minimizing production risks. Automated tracking, alarm functions, and a complete change history help maintain quality, reduce downtime, and streamline change management.

OT SECURITY

Enhance OT security by identifying, assessing, and providing actionable insights on Common Vulnerabilities and Exposures (CVEs) that impact production assets. By proactively mitigating risks, it helps safeguard industrial environments, ensures compliance with standards like NIS2 and NIST, and strengthens resilience against cyber threats—ensuring continuous and secure operations.

VULNERABILITY

MANAGEMENT

MANAGEMENT

Access comprehensive criticality scores and in-depth asset insights to identify, prioritize, and mitigate high-risk threats—ensuring a proactive and effective cybersecurity strategy for your entire equipment landscape

ASSET

MANAGEMENT

MANAGEMENT

Manage assets with a comprehensive view across factories, organizations, or sites, regardless of the vendor. Centralized visibility enables better monitoring, management, and optimization of all connected assets, helping to identify inefficiencies, detect unauthorized changes, and improve overall operational security and performance.

NIS-2 / NIST REGULATORY

COMPLIANCE

COMPLIANCE

Assure full traceability and automated documentation to meet industry standards like NIS-2, NIST, FDA, and GxP. With detailed audit trails, controlled release processes, and system validation, it simplifies audits, reduces compliance risks, and helps meet regulatory requirements.

OUR

CUSTOMERS

TRUSTED BY MANY

CUSTOMERS WORLDWIDE

GLOBAL PARTNERS

OF THE WORLD’S LARGEST MANUFACTURERS USE OCTOPLANT

INDUSTRIAL DEVICES RELY ON OCTOPLANT EVERY DAY