CHANGE

MANAGEMENT

APPROVE, TRACK,

AND AUDIT CHANGES

BEFORE THEY BECOME PROBLEMS.

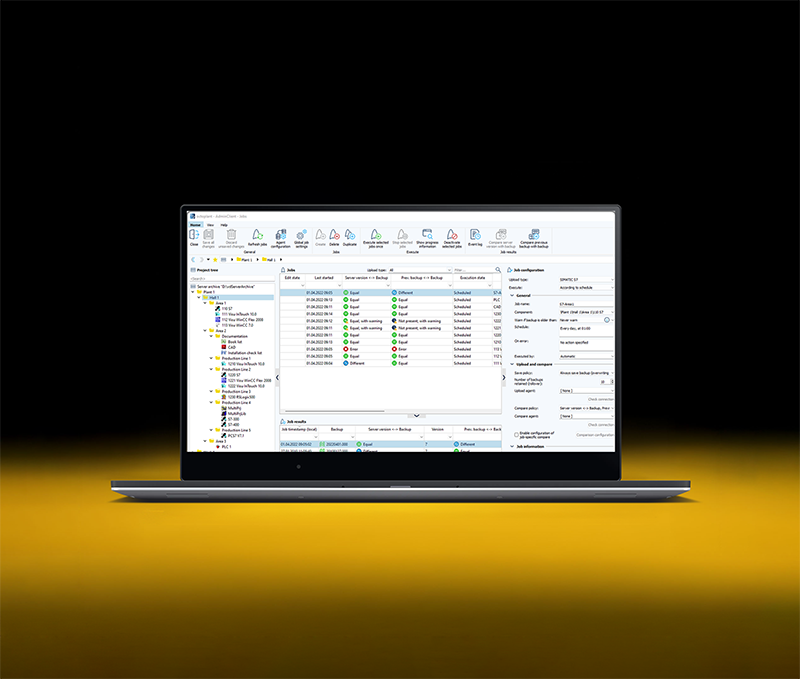

Octoplant ensures no change goes undocumented or unapproved. Every action is logged and traceable, with optional approval workflows that prevent risky or unauthorized updates. This structured approach to change management is especially critical in industrial environments where uncoordinated modifications to PLC programs or device configurations can lead to unplanned downtime, safety hazards, or compliance violations. Octoplant connects change events directly to responsible users and devices, enabling manufacturers to maintain full oversight of who changed what, when, and why—backed by clear documentation and configurable rules for accountability.

Customizable

change approval

change approval

processes aligned with internal procedures

Role-based

access control to define responsibilities across engineering and operations teams

Automatic change tracking

with user IDs and timestamps

Centralized logbook

of all configuration and program changes across systems

Alerts and

notifications

notifications

for unplanned or out-of-process changes

Centralized Version Control

includes built-in version control

Full

traceability

traceability

of actions across multi-site and multi-vendor environments

Stay Ahead of Every Change

In fast-paced production environments, untracked changes can quickly escalate into costly disruptions. octoplant brings order to change management by turning every update into a controlled, transparent event. Whether changes are made manually, automatically, or remotely, octoplant ensures they're captured, approved if necessary, and available for review—creating a defensible audit trail and reducing the risk of system instability. This proactive approach helps engineering, maintenance, and IT/OT teams stay aligned, avoid finger-pointing, and keep production running safely and efficiently.